Hall You Could Wish For

$136m is a lot to throw at a refurb, but Hamer Hall’s technical department isn’t complaining.

Text:/ Christopher Holder

The number of women’s loos have doubled. It might sound like an irrelevant stat for a magazine such as AV, but it speaks volumes. When Hamer Hall was designed back in the ’70s not much had fundamentally changed in the design of concert halls for 200+ years. They were big auditoria designed for big symphony orchestras to stretch their legs. But as the women’s loos factoid suggests, the designs were becoming increasingly paternalistic and antiquated.

Since Hamer Hall’s opening in 1982, ‘concert halls’ have become multipurpose and multi-functional. Concert halls need more than an announcer’s tannoy, they need full-blown concert PA systems and a room that can handle high SPL.

Hamer Hall for some years now has been doing its darnedest to move with the times. In fact, prior to it closing down for renovations, there were actually more amplified gigs than there were Melbourne Symphony Orchestra concerts. Stand-up comedy, Circus Oz, musical theatre, rock and pop concerts… Hamer Hall was catering to performers and an audience its designers simply couldn’t have foreseen in the ’70s.

The $136m overhaul is clearly significant – financially, aesthetically, and practically. What’s more it’s a triumph for the technical team. Led by Head of Production, Frank Ward, the tech team’s initial ‘blue sky’ brainstorming has been rewarded with a world-leading performing arts centre.

But first, the acoustics.

THE ACOUSTIC PROBLEM

The Hamer Hall upgrade recognised the fact the auditorium itself needed urgent attention. The sound of the hall was seriously lacking. What could only be described as an acoustics dream team was engaged. Marshall Day and Kirkegaard Associates tag-teamed on the acoustics, while Schuler Shook undertook the theatre consultancy duties.

Identifying the problems wasn’t difficult. The MSO complained they couldn’t hear each other or the room/audience – there was a serious disconnect. This unfortunate acoustic quirk of the room meant the stalls area nearest the stage (for the people in the expensive seats) was less than immersive. In fact, committed MSO patrons would often plumb for the cheap $25 tickets in the dress circle because it provided a better sonic experience.

Superficially, since the refurb, the hall doesn’t look transformed. The differences may appear subtle but they are profound. Acute angles in the stage surrounds have been softened. The upper balcony ‘arms’ and walls near the stage have been removed, allowing a more pleasing reverberation to develop in the room. The floor area of the stalls has been narrowed by three metres and in so doing has decreased the overhang from the circle above – which has made the room more acoustically ‘intimate’, providing for a greater sense of envelopment. Good envelopment brings patrons psycho-acoustically closer to the orchestra and comes as a result of hearing diverse sources of reflections – not just the wall next to you.

Lastly, as a couple of acoustic glacé cherries, a flocked paint has been applied to the rear walls to reduce some of the HF zing for people nearest the boundaries, and deployable acoustic drapes are available to dampen down the room further if required.

How’s it sound? As of going to press, Hamer Hall had only been open a week and the MSO hadn’t actually had it’s first public hitout. Saying that, in tests, the MSO and Australian Chamber Orchestra are much, much happier. Mostly, thanks to an amazing innovation – a variable acoustical reflector.

REFLECTOR REFLECTIONS

Any acoustical performance on stage is going to need a reflector overhead of some sort in order to take the sound and bounce it back to the musicians so they can hear themselves playing on stage and also to reflect it out into the audience. Building such a reflector permanently into the architecture isn’t such a big deal, but when you’ve got a rock band with thousands of watts of foldback going full throttle, these reflectors become a total sonic liability.

Previously, Hamer Hall had the traditional ’80s acoustic dishes suspended above the stage but they provided patchy assistance at best — brass wasn’t getting much of the violas but plenty of the violin, by way of (a fictional) example [nobody gets much of the violas – Ed].

What’s more, the area above the stage was a mess. The acoustic dishes weren’t as ugly as they could have been thanks to the even-uglier PA rigging and lighting bars concealing them from full view.

So the trick for Hamer Hall was to design an elegant system that could be flown in and out, and, what’s more, not interfere with the operation of fly bars and winches. As far as the team was concerned, such a system didn’t currently exist anywhere, so it needed designing from scratch. Bob Shook, principal of US-headquartered theatre consultants, Schuler Shook, picks up the story:

“We wanted to ensure the hall had a new degree of technical sophistication in order to keep to a schedule: the Melbourne Symphony on Wednesday night, Tina Arena on Thursday night and Circus Oz on Friday night. And the people that do that want the minimum of labour and time spent going from one setup to another.

“Schuler Shook introduced the idea of the ‘Technical Zone’ over the stage. It’s an insertion into the auditorium. Its primary purpose is to contain a sophisticated degree of mechanical and automated rigging. It allows stage lighting, stage scenery and stage effects to be raised above the stage with a minimum of person-power. And it also supports the new acoustical reflector.”

Ah, yes, the pièce de résistance, the acoustical reflector…

Bob Shook: “The new acoustical reflector is the result of a collaboration between the acousticians, Kirkegaard Associates and Marshall Day, Ashton Raggatt McDougall (ARM) as architects and Schuler Shook as theatre consultants. An acoustical reflector has to fulfil so many different roles: It has to first and foremost work for the orchestra, and for other different types of acoustic music performed in Hamer Hall. It also has to look like it belongs in the space. That was ARM’s task. Schuler Shook’s role was to design something that could be there when necessary and not be there when it wasn’t, and to be there in different configurations depending on the type of event.

“The reflector itself weighs about 12 tonnes and can be reset into a number of different configurations [i.e. it’s not just either up or down; it can be re-shaped] and minimised when it’s not needed for non-symphonic events – all in less than a minute.”

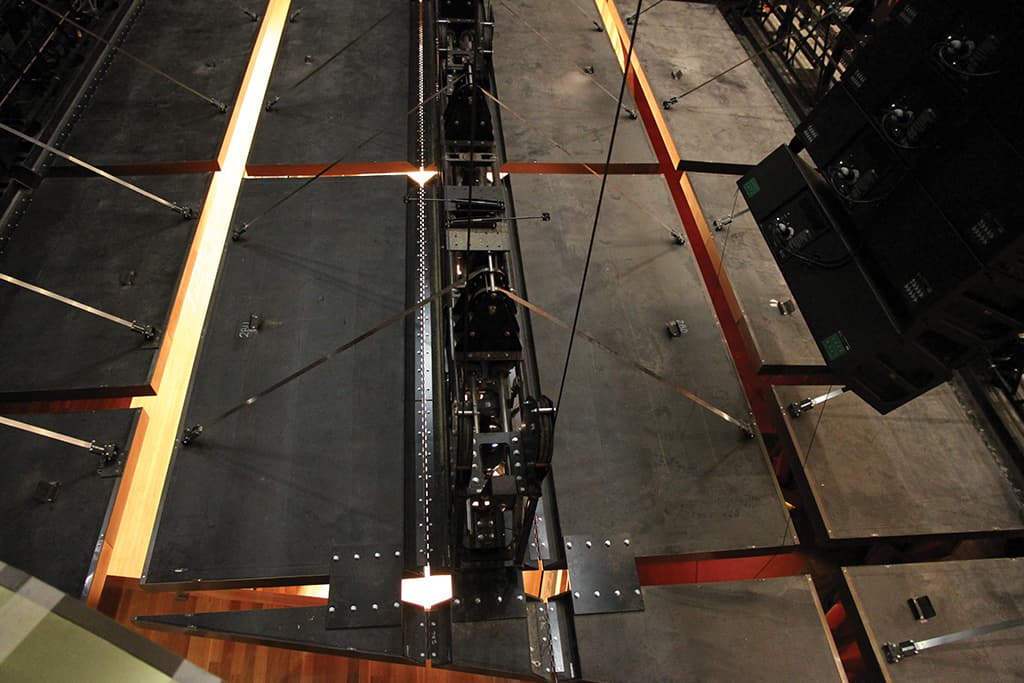

The design was handed to Jands which engineered the five panels, and according to all sources did so ‘magnificently’. It fulfils quite a formidable brief: the assembly of each of the five panels tilts on four axes; the panels house the orchestra lighting; the panels contain penetrations for the microphone reelers and pin spots to drop through; there are slots for the flybars and some lighting rig to fly under the reflectors; each panel is three metres wide but is only 0.8 metres when folded away; one of the panels has a middle section that lifts independently to allow passage for the centre speaker cluster…

Jands built the frames, with giant crank shafts and ASM steel-band hoists doing the articulating. It engaged a boat builder to manufacture the exterior – a fibreglass resin and aluminium-honeycomb panel which met the acoustic requirements, with a bronze skin providing the aesthetic. We’ve put a short video of the panels in action on our website. Have a look and I’m sure you’ll agree that these panels are as beautiful as they are ingenious.

BACK OF HOUSE JOY

Hamer Hall was designed to accommodate a resident orchestra. Bumping in and out huge productions wasn’t on the radar 30 years ago. But in more recent years the load-in facilities have proven to be a real bottle neck.

Under the direction of Schuler Shook’s Jim Hultquist, the dock has now doubled in size and, thankfully, doesn’t share space with the food and beverage services. The back of house hydraulic scissor lift is now a capacious 8m x 3m, with egress to a spacious room — more than enough real estate for a mass choir or AC/DC’s backline. A healthy 3m-wide door now opens to the staging area – enough to back a car through, or indeed (more likely) huge sleds of equipment onto stage.

Overhead, the flying system has been completely overhauled. The previous setup was a labyrinthine nightmare. And with the new Tech Zone being instituted (with its 70 tonnes of steel, including five tonnes of bolts!) it allowed all the new ASM stage winches to be housed above the choir sides in acoustically treated rooms. A Waagner Biro automation system has been implemented and also controls the two stage lifts which retain their old motors. The new flying system is capable of picking up 16 tonnes of staging equipment and is millimetre accurate. All this work was carried out by Jands.

DREAM PA

Filling the acoustically-transformed auditorium with amplified sound is a new Meyer Sound PA. It replaces the old Meyer MSL4-based system and was selected as a result of a rigorous appraisal process. With Meyer’s D-Mitri acting as the digital matrix backbone, 12 system inputs feed a whopping 102 outputs. From input stage, there are three Digico stage racks (two on stage and one upstairs for the flown orchestral mics) addressed by the two Digico SD7 consoles via an Optocore fibre-based network loop. The audio travels out of the Digico systems via AES digital into D-Mitri, with D-Mitri going about its business in AVB (Audio Video Bridging protocol) via a dual-redundant Cat-6A network.

Nick Carol, Head of Sound: “We have two DCM [D-Mitri Core Matrix] units. One’s a redundant unit. Then from three DCPs [D-Mitri Core Processing units] – one of them is a spare – we run AVB to all the output/input boxes and two AVB streams on different switches to get to the different nodes.”

With 102 outputs you’d think perhaps that every speaker in the house is individually addressable. Erm… not quite.

The main L/R Milo arrays (nine elements per side) are complemented by four Melodie delay hangs (six per side with a 5600HP flown sub). A low-profile centre cluster of eight Minas takes care of conductor announcements. UPM-1P speakers are used for under-balcony fill to refresh the high-end deeper into the room. Two lines of front fill speakers are installed, depending on whether the orchestra pit is being used or not. Additional, high-powered front fill can be brought in to line the front of stage for high-SPL shows.

If seating is occupying the orchestra pit floor space, the main PA hangs can track back, downstage, by 2.5 metres to ensure those front rows don’t have sound directly overhead.

The system design allows for a ‘clean stage’ configuration – for dance events, AGMs, smaller amplified shows and the like – where two layers of recessed Mina arrays in the stage surrounds take care of infill duties. These arrays sit behind perforated panels and are all-but invisible. For acts that require a greater level of amplification and have on-stage monitoring, the technical team can bring out ground- stacks on stage – each comprises five Meyer Melodie mid/high units and two 700HP subs.

In its acoustic configuration, doors close over the ‘invisible’ in-fill arrays, ensuring the room gets the full benefit of those crucial first reflections from stage. Saying that, two slots remain either side of stage for Meyer’s brand new CAL steerable array to ‘poke’ through. CAL is being used for emergency announcements and in conjunction with the Mina centre cluster when the conductor has something to say. It’s the first installation of CAL worldwide.

How’s it sound? Unfortunately, I don’t have 100,000 people following my tweets and I’m not vice regal, so AV didn’t make it to the opening night. But AV attended the third night of Philip Glass’s Qatsi trilogy (12 musicians, half of which were miked up, the other half were playing synth sources) and was duly impressed. It wasn’t a high-energy show, but the PA provided an effortlessly sweet response. It was ‘sound reinforcement’ in the true sense of the word – just enough, and delightful. Meanwhile, Nick Carol, Head of Sound, can’t wipe the smile off his face.

Nick Carol: “We had ([legendary system optimisation engineer)] Bob McCarthy in to align the PA and like us he was amazed by how even the sound pressure levels are in this room. Front to back he couldn’t remember a more even room.”

COMMS

The Hamer Hall refit includes a new Riedel digital intercom system. This system comprises an Artist 128 matrix, a Performer digital partyline system and an Acrobat digital wireless beltpack system.

The Artist matrix provides the brains for the entire communications and BOH backstage paging matrix. Critical areas, such as the stage manager’s desk, the FOH mix position and the lighting control room are all fitted with Artist panels, allowing discrete point-to-point communications alongside the traditional ‘loops’. The power of the matrix also allows stage managers to make BOH backstage pages from anywhere, including their wireless packs, in full digital quality.

Dual power supplies and redundant CPU cards means this system-critical infrastructure is as bullet-proof as you can get.

The Performer partyline system replaces the traditional wired beltpacks found in most theatres. By using AES digital signalling, they are able to get two channels of full-range audio down a standard single one-pair audio cable with minimal noise floor. This means the overall volume of the beltpacks can be kept down, minimising fatigue on long shows. By utilising the new audio cabling throughout the venue, the technicians now only have one patchfield to manage instead of separate comms and audio patch points.

The Acrobat wireless system uses 1.9GHz DECT (cordless telephone) technology to talk to 12 wireless beltpacks to operate in full-duplex from a single base. Six distributed antennae allow technicians to roam freely around the backstage and BOH areas without dropout. Since these beltpacks are connected directly to the matrix via MADI, each beltpack acts like a ‘wireless panel’; giving the users access to discrete calls and advanced functionality. By going to the 1.9GHz digital range, Hamer Hall frees up spectrum to allow for the digital dividend without compromising their widespread 2.4GHz wi-fi networks.

The system was designed in collaboration with Riedel Australia, and was installed by the KLM Group.

LIGHTING

The Hamer Hall lighting department, led by Adrian Sterritt, also had its fair share of ‘firsts’.

Above the stage, the new acoustical reflector takes care of work-a-day house lighting for the orchestra. The reflectors incorporate 55 tungsten source lamps for an even white wash (on State Automation sine wave dimmers). The moving rig now packs 18 x Vari-Lite VLX wash lights, 21 x Robe MMX spots, 28 x ETC D40 Lustr LED fixtures, ETC Source Four Seachangers and ChromaQ cyc floods.

Adrian Sterritt: “We would like to have gone all-LED if possible, but we couldn’t because there is no profile moving head that’s bright enough at this point. So that’s why we went with the MMX which uses an 800W fast fit globe. It also punches above its weight for the 800W, it’s full of built-in features and it is quite fast. Meanwhile, the Seachangers give us a great variety of light – full CMY mixing. It means that we can turn off the other lights, go fanless, and still have the Seachangers to change colour – which is important for orchestral nights. It’s a similar situation with the ETC Lustrs – fanless. On orchestral nights we can still go colourful without fan noise.”

Upstairs in the control booth the lighting department welcomes a brand new PRG V676 4000-channel lighting desk. For redundancy’s sake an additional Mac runs the V676 software.

Adrian Sterritt: “The V676 is streets ahead. It’s designed to do moving lights, data, and it interfaces with media servers much better. You can configure it in any way you want, and, with the touchscreens, it’s very easy to jump around quickly.”

A Virtuoso network runs the desk while an ArtNet network talks to the 384 State Automation SCR dimmers. On the end of the ArtNet network are a plethora of PathPort nodes (for turning the ArtNet into DMX).

Adrian Sterritt: “We tried to future-proof the venue by putting in so many network points. We’ve got a fibre ring around the venue and we also have network points from the fibre to breakout, so we can get network almost anywhere in the building.”

ALL IN THE EXECUTION

In extensive, expensive and complicated renovation jobs such as this, rarely does the operator, the engineer, or the resident ensemble really get what they want. Everyone goes in with the best intentions but budgets and technical compromises more often than not blunt the scope and execution.

Occasionally we hear about good news stories, and Hamer Hall looks to be one of them. From the outset, Head of Production Frank Ward sat his team down and asked them to forget about budgets for a minute and simply dream – what would their ideal setup look like? ‘Sure, sure…’ you can sense the scepticism that must have been in the room even now. But according to Frank, 36 of the 40 points on the wish list have been realised. And in my book, I give that an ‘A’.

CONTACTS

Alliance: Arts Victoria, Major Projects Victoria, Arts Centre Melbourne, Baulderstone

Schuler Shook (Theatre Planners): 0438 382 408 or [email protected]

Marshall Day (Acousticians): (03) 9416 1855 or [email protected]

Kirkegaard Associates (Acousticians): www.kirkegaardassociates.com

Ashton Raggatt McDougall (ARM – Architects): (03) 8613 1888 or www.a-r-m.com.au

Jands (Staging): (02) 9582 0909 or [email protected]

Meyer Sound (PA): www.meyersound.com.au

Group Technologies (Digico): (03) 9354 9133 or [email protected]

KLM Group: (03) 9320 3444 or www.klmgroup.com.au

Riedel Communications: (02) 9699 5579 or www.riedel.net

ULA (Robe): 1300 852 476 or www.ulagroup.com

RESPONSES