TAG’s Warehousing Goes Green

TAG moves into its new Sydney warehouse and makes sustainability a serious priority.

Text:/ Christopher Holder

“If you can; you must.” If it’s not their precise words, then it’s certainly the sentiment of TAG directors, Maxwell Twartz and Anthony Russo. In other words, if you have the means to invest in sustainable business solutions, then just do it — “this is the planet we’re talking about,” as Max noted.

When TAG bought a new warehouse in Sydney’s Kings Park, it determined it would make sustainability a priority. There are probably conferences, or highly-paid consultants that might assist but the TAG approach is always hands on. Max, Tony and others at TAG just started reading and having discussions with industry recycling experts, to discover out what the state of the art is in machinery and recycling management.

PRICE TAG?

AV: Did you draft up a business case for investing in warehouse sustainability?

Max: If you go into a venture like this looking for a business case for sustainability investments, then you’re really going about it the wrong way. Not to say there isn’t a business case, but for us that’s a happy spinoff, not the main game.

I’d suggest that if you can afford to make those investments then you absolutely should.

Only then, after you make the investments, do you fully realise just what a virtuous circle you’ve created. You begin to create efficiencies and savings in ways that are, at times, impossible to predict.

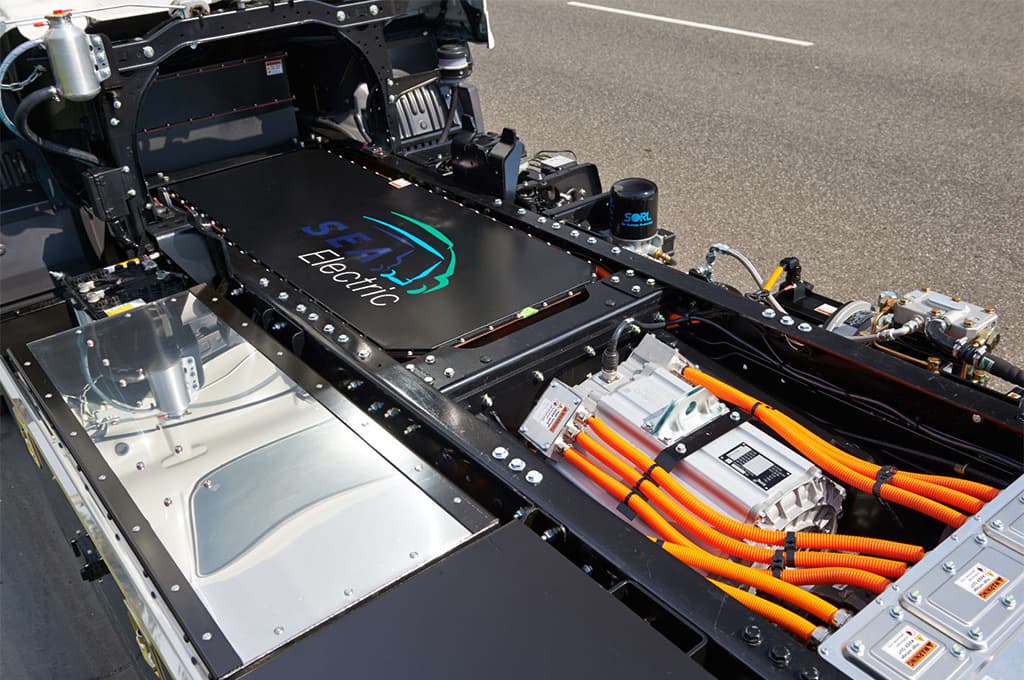

For example, our eight-tonne electric truck is, on paper, a ridiculous investment [there’s not much change out of A$300,000 — Ed.]! If it was left to the accountants they’d suggest it’ll take way too long to see any savings from using electricity rather than diesel. But every time it hits the road it will serve as a powerful reminder to people that TAG is serious about the environment and will encourage others to get serious.

Tony: Our investment in the eight-tonne truck was two steps above where we we could have bought in, but the extra investment made sense to us. Same goes for every piece of machinery we buy — each is more than fit for purpose and each has a narrow but very important role, like eliminating bubble wrap from our operations.

“”

We don’t set ourselves up to be world leaders, or say this warehouse is some kind of beacon to the industry — we’re just doing the best we can and hope it inspires others

EV 8-tonne truck: Primo modified Hino truck ordered from SEA Electric in Dandenong, used to take care of Sydney-wide deliveries.

Solar panels: A 100kW ABB inverter system not only covers the warehouse’s needs but also accounts for all of TAG’s commercial power requirements in Sydney and Melbourne.

Plastic pallet wrap machine: TAG uses 25 micron plastic and a Lantech machine that stretches the wrap 300%, resulting in less plastic use.

GLOBAL TIMES

AV: It’s great to invest in sustainability with all the right motivations but how likely is it that some of what you’re going here will be mandated sometime soon anyway?

Tony: If not by the government, then probably by your investors or suppliers. It’s true that many of the bigger companies we represent are now asking us what we are doing for the environment and it’s good to be able to demonstrate just how serious we are — we are not just ticking the boxes.

AV: It must be personally rewarding to now see the warehouse in action?

Tony: The generation coming through is very concerned about the environment and they’ll be the ones to take what we’ve done here and make it even better. And it’s personally rewarding to know we’ve given them the tools and hardware to really get started.

Hard plastic chipping machine: some plastics aren’t so easily recyclable, like pallet strapping. Chipping that plastic reduces the number of vehicle trips it takes to dispose of. TAG is confident it will find outlets that wish to reuse the resulting plastic powder.

Cardboard shredder: A special machine takes waste cardboard and turns it into ‘void filling’ material for TAG’s dispatch department.

Miyawaki forest: high-density landscaping (traditional Japanese style) to create a thriving biosphere on the property’s perimeter. Elsewhere a Mediterranean combination of fruit trees are planted.

TAG: YOU’RE IT

AV: For years now you’ve been running social programs and going out to remote communities with your equipment. You’re now calling those programs ‘Nakama Arts’ and you’ve got Chris Hamer-Smith managing that program. It’s all getting pretty serious, isn’t it?

Max: For years we’ve done things under the radar but we’ve learnt now to talk about what we do, not to get a pat on the back but to inspire others to do their own thing. We want to influence others for good.

The same applies to what we’ve done with the warehouse. There’s nothing we’ve done that’s not reproducible in thousands of other warehouses. We don’t set ourselves up to be world leaders, or say this warehouse is some kind of beacon to the industry — we’re just doing the best we can and hope it inspires others.

AV: As a competitor can I give you a buzz and talk some more about what you’re doing?

Max: Sure, drop by and charge your EV! We might be competing for market share but sustainability is something we can all agree on. You might have insights into ways we can improve what we’re doing and I know we’d be happy to share our knowledge.

The first piece of advice we’d offer is: just get started.

TAG: tag.com.au or (02) 9519 0900

RESPONSES